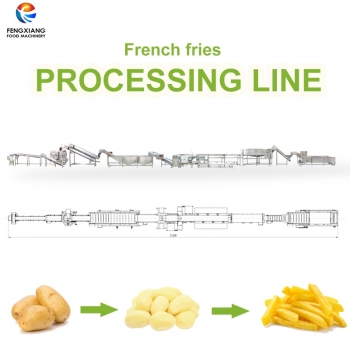

The potato french fries processing is including potatoes washing, peeling to potato slicing, potato weighing, and potato packaging.

1. Potato cleaning and Peeling:

|

Using bubble washing machine to remove dirt, debris from the potatoes. The equipment includes a filtration system that cleans impurities from the water, saving resources and improving efficiency. The peeling process uses advanced mechanical peelers with rotary grinding and high-pressure water jets. These machines efficiently remove potato skins with minimal waste. |

2. Sorting and Cutting:

|

In this step, shredding the potatoes into sticks of specific sizes, with high efficiency, energy saving consumption, simple operation |

|

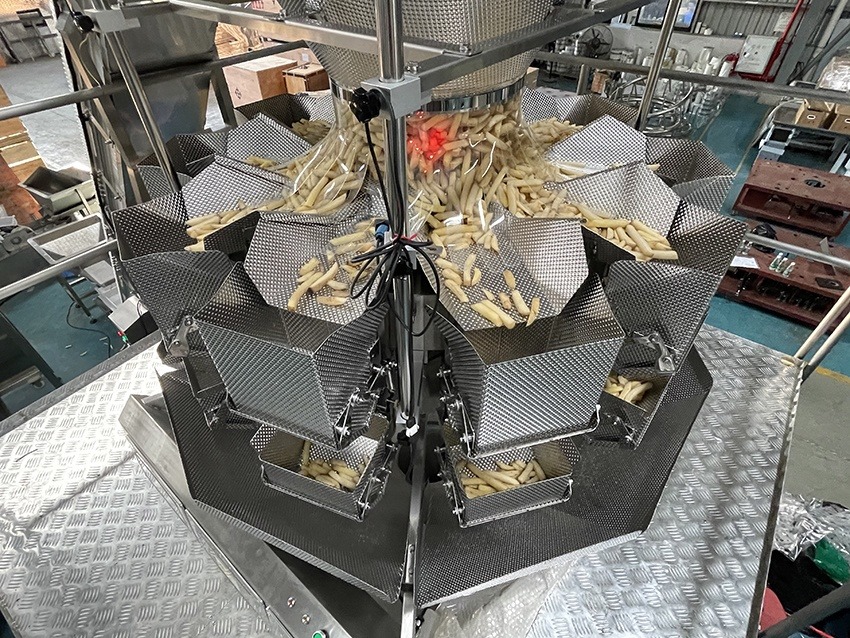

3. Weighing and packaging

|

Depending on customer needs, the processed fries can be packaged or frozen. |

Benefits of the potato chip Solution:

- **Efficiency**: High automation reduces labor costs and boosts productivity.

- **Modular Design**: Flexible configurations meet diverse product specifications.

- **Easy Cleaning**: Food-grade materials resist corrosion and are easy to clean, meeting international hygiene standards.

| Document | Download |