Fresh Sweet Corn Kernel Production Processing Solution Line

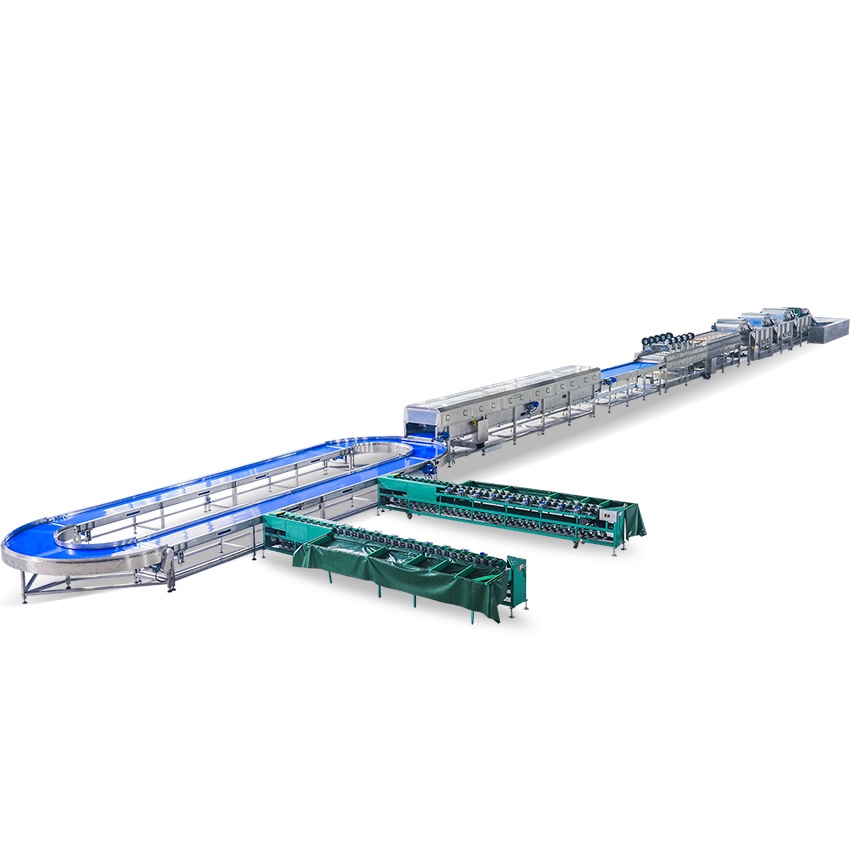

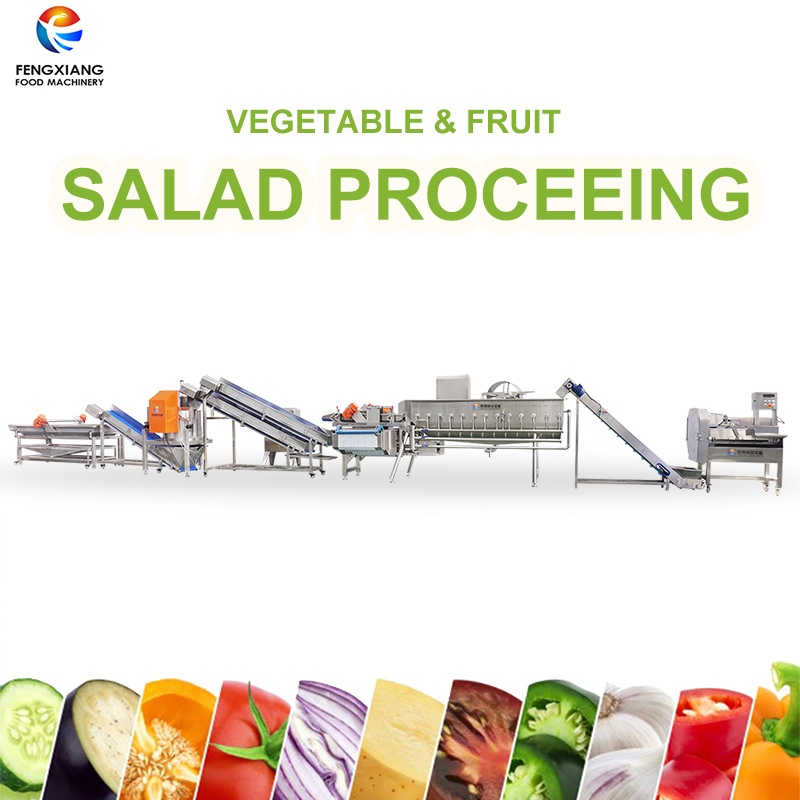

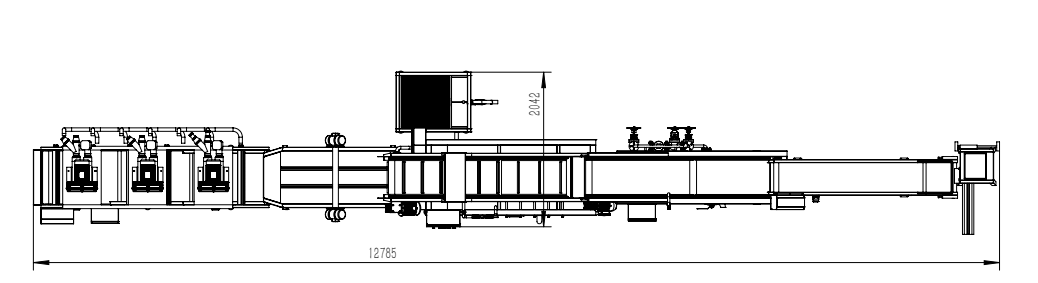

The sweet corn whole kernel processing line can be customized according to customer requirements, It is a completely automatic processing line which is for vegetable and fruit pretreatment. Sweet corn processing solutions that could custom built to suit your needs and it's easy to use and to maintain. The process including Sweet corn threshing, corn kernel blanching, corn kernel cooling and cleaning, Dewatering, Air drying and packaging. From freshly picked sweet corn to a packaging corn kernel, remove excess water and with IQF freezer dvanced cold room can store frozen sweet corn products for a long time with outstanding performance.

Detail

The whole production line can be customized according to your needs

|

|

►Sweet corn threshing machine: Corn shelling machine can adjust according to the size of the corn cob automatically, suitable for threshing various sizes of corn, and the depth of threshing can be adjusted. Suitable for threshing kinds of fresh corn, sweet corn, waxy corn and frozen corn after thawing. |

|

►Sweet Corn Remove impurities |

|

|

|

►Corn blanching - cooling cleaning - dewatering - air drying process: To keeping the grains neat and tidy, prevent the core from being cut off, select the grains, remove the whiskers, cores and other impurities, and heat immediately. |

Finished Effect of Sweet Corn

According to the need, we can also provide the IQF processing plant.

Besides corn pretreatment processing line, we also can make beans production line, french fries productioin line, crisp production line, vegetable processing line, fruit drying processing line, vegetable drying processing line, fish processing line, seafood and fish production line.

| Document | Download |