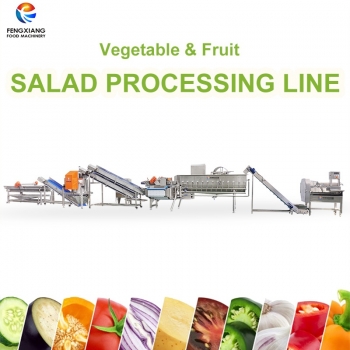

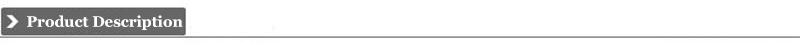

Vegetable And Fruit Salad Cutting Washing Drying Packaging Processing line

The vegetable fruit salad processing production line is mainly used for cutting, cleaning, air-drying and packaging salad. The design of the whole line is user-friendly, save water and workers, the degree of automation is high, the cleaning effect is good, and the material is not damaged.

The Specification of Automatic Salad Production Line

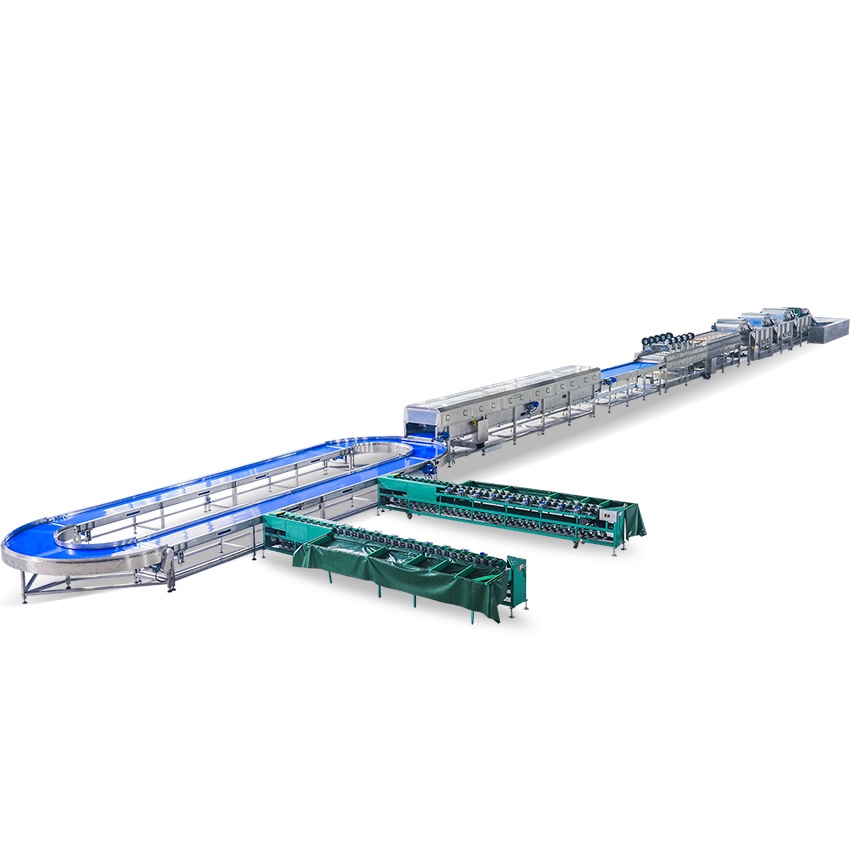

Inspection table → Vegetable cutting → Liftting conveyor → Washing → Dewatering → Packaging→Finished goods

|

Machine |

Dimension |

Voltage |

Power |

Capacity |

|

Inspection Table |

Can be customized according to your need |

|||

|

FC-360L Machine |

1020*760*1370 mm |

220V |

0.75KW |

1500-2000KG/H |

|

Lifting Conveyor |

Can be customized according to your need |

|||

|

XWA-1300 Vortex Washing Machine |

4088*1632*1813mm |

380V |

4.87kw |

1T-3T/h |

|

Continuous Dewatering Machine |

1590*1170*2030mm |

380V |

5.5kw |

500-800kg/h |

Feature

1) Can clean vegetables or fruits while saving water

2) It is suitable for vegetable and fruits.

3) Continuous and high output, can be matched with large-scale production lines.

4) Easily operation and simple structure.Corrosion resistance,longer service life

5) High efficiency and high automation, multi-function cutting into various shapes, thorough cleaning and high dehydration rate.

Details

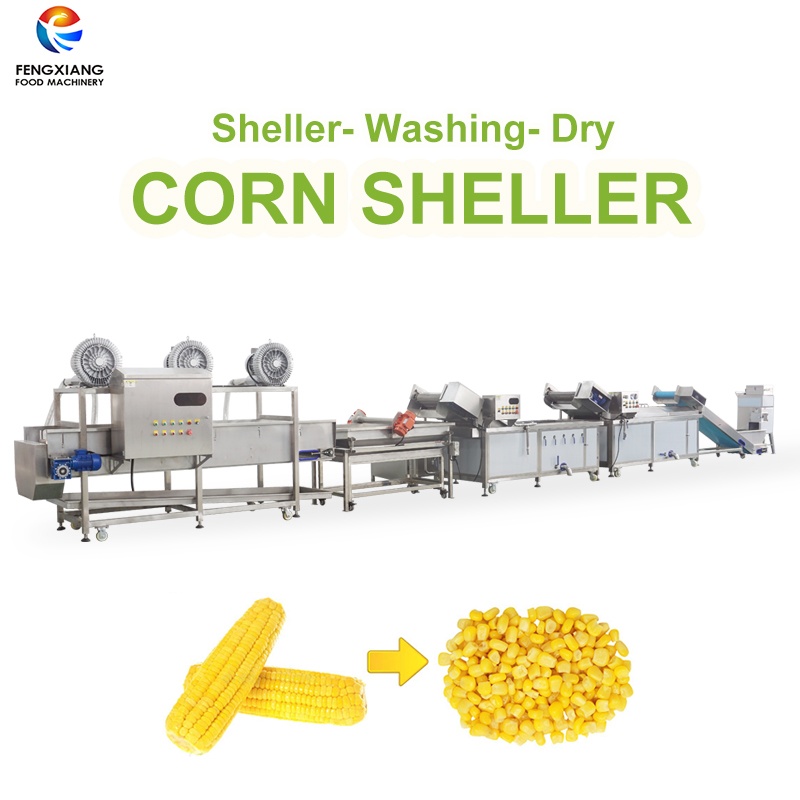

►Vegetable cutting

|

The multi-functional vegetable cutting machine has a double frequency modulation function, which can be used to cut leeks, celery, green onions, cabbage, long beans, cucumbers, potatoes, sweet potatoes, onions, eggplants, winter melons, apples and pineapples and many other melons and fruits and vegetables to chop, cut all shreds, dice, cut sections, cut into cubes and other work. |

►Vegetable washing

|

The vortex vegetable washing machine is composed of tank body, sediment isolation net, lifting device, bubble generating device and other components. |

►Vegetable dewatering

|

When the centrifugal dehydrator machine runs, the material is evenly distributed on the inner wall of the drum under the action of centrifugal force. The liquid attached to the material is thrown to the inner wall of the shell through the hole on the wall of the drum, and discharged from the outlet after collection, while the solid material is left in the drum to complete the separation process of centrifugal filtration. |

Finish Products:

The finished vegetables are dry and undamaged, processing effect is good.

1. We are always devoting our time and energy to the industry of food processing machinery, and to research, develop, deep work and innovate in the field of fruit and vegetable machinery, hoping that our service can meet customers' satisfaction, and our products can truly create value for our customers.

2. We adhere to the value of "customer-centricity". From the user's perspective, to design various practical solutions to make food processing easier and better, so that the processed food is safe, hygienic, tasty and nutritious.

3. Today, Fengxiang machinery, just like the founder's original intention, has flown to the world and continued to fulfill the dreams of many customers.

4. In the future, we are committed to becoming a "world-class service provider with our fruit and vegetable solutions".

| Document | Download |