From an African client, they aim to turn fresh fruits into dried fruits through a complete production line.

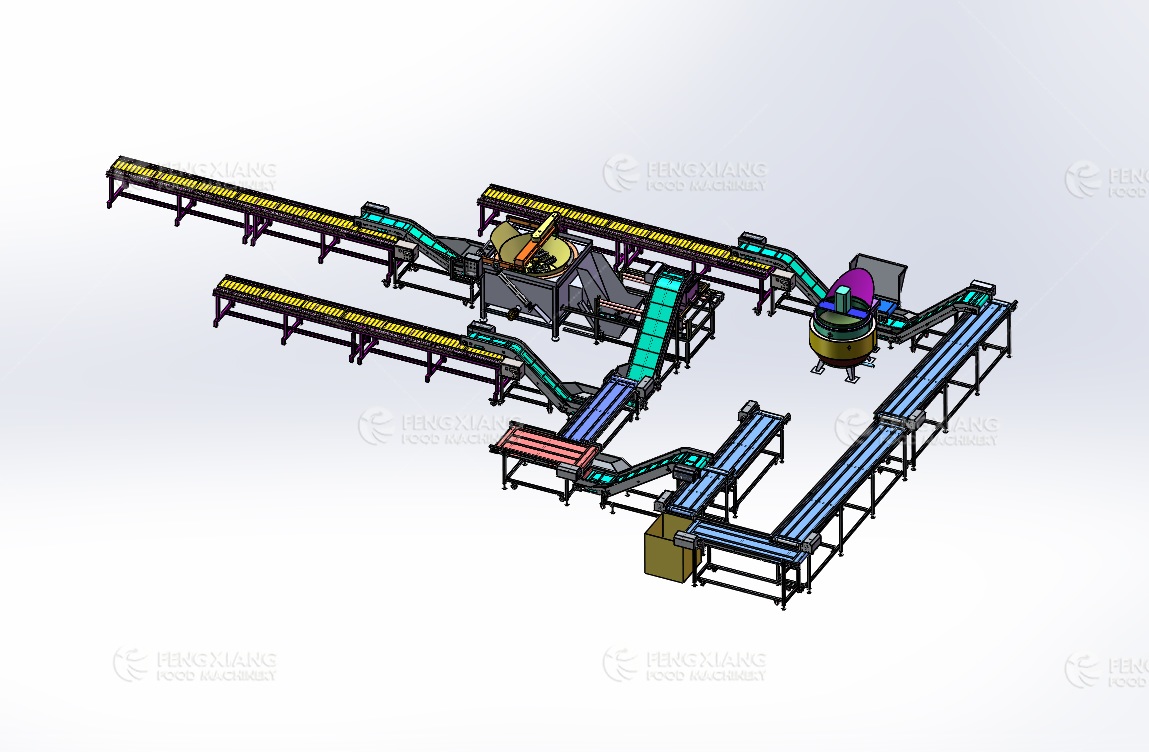

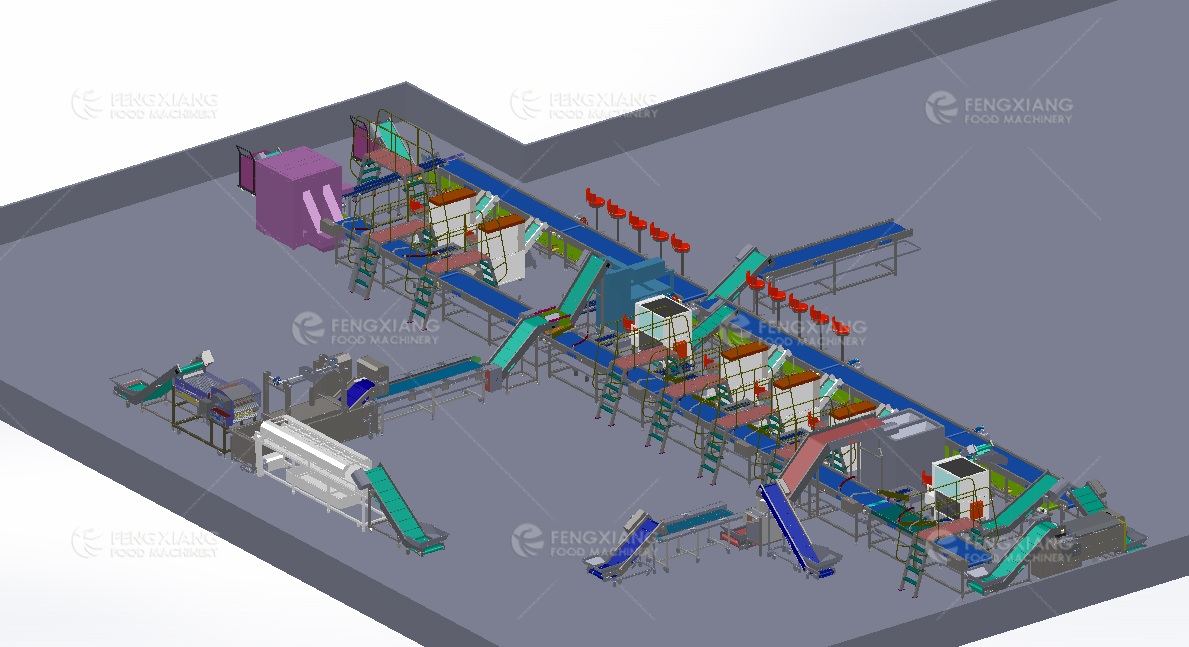

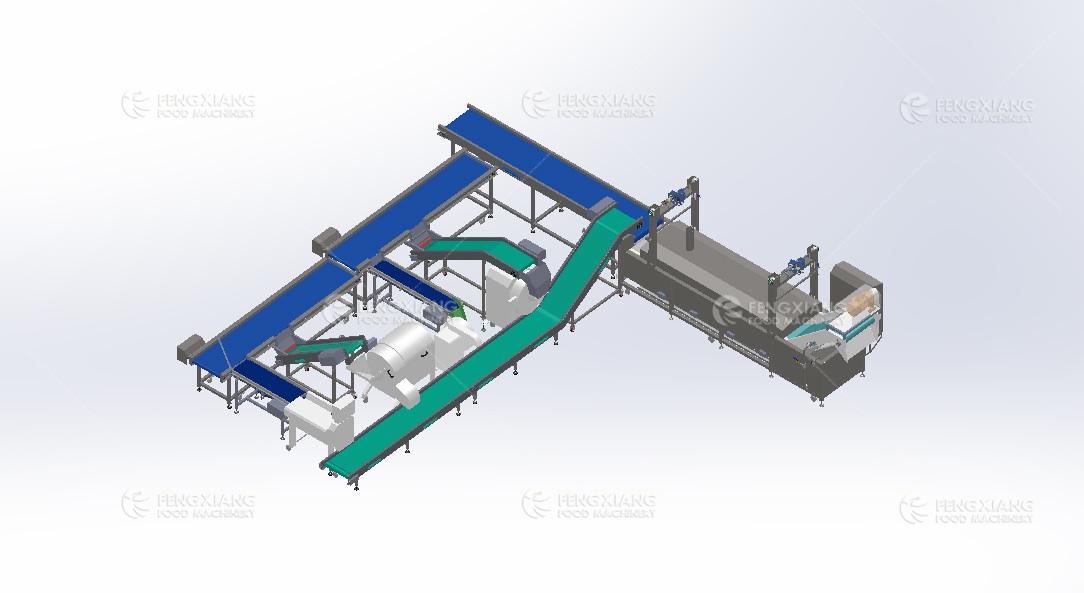

We designed a dried fruit processing line solution that meets their requirements. The dried fruit processing line including fruit washing, peeling, slicing or dicing, drying, weighing, and packaging.

This solution is suitable for processing various fresh fruits like bananas, pineapples, cashews, kiwis, and mangoes.

Fruit washing and peeling are the first steps impacting the subsequent dried fruit processing. Batches of fresh fruits are get turned in the washing tank to remove impurities and dirt from the surface.

The unique appearance of dried fruits attracts consumers. Slicing, dicing, or cutting fresh fruits into pieces makes the drying process more faster.

Fruit drying takes out extra water from the pulp while keeping the original fruit texture. Our fruit drying machine, uses heat pump technology, evenly dries fruits.

Dry fruit weighing and packing are key for deciding how dried fruits look and show up for customers. The dry fruit processing production line efficiently handles large quantities of fresh fruits, not only providing high-quality products but also help clients in the transfor fresh fruit to dried fruits.

From design solution to after-sales service, we have consistently served clients diligently, striving to provide a satisfactory response.