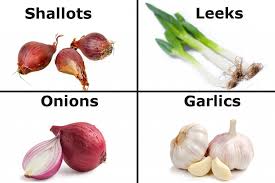

Speaking of garlic and onion, we believe that everyone loves and hates it. Under the tightly packed appearance, it has a delicious taste and is an indispensable ingredient in cooking. As an important cash crop, garlic and onion are an important source of farmers' income. However, with the diversification and standardization of food processing, the low-cost sale of raw materials can no longer meet the needs of businesses. In recent years, the planting area of onion and garlic has been continuously expanded, and the mechanization of onion, ginger, and garlic production has also developed to a certain extent.

In addition, foreign countries regard onions as the "queen of dishes", and they are particularly fond of them. It is found that different exporting countries have different preferences for onions: Singapore, Malaysia and other places prefer smaller onions; European and American countries prefer larger ones; and Russians prefer skinned onions. The international market has strong demand for deep-processed products of onion, garlic, and ginger. Depending on the size of the onion, you can use a classification device to sort it. By adjusting the classification aperture, the ingredients are classified and screened reasonably, so as to improve the efficiency and enter the next processing step.

In addition, foreign countries regard onions as the "queen of dishes", and they are particularly fond of them. It is found that different exporting countries have different preferences for onions: Singapore, Malaysia and other places prefer smaller onions; European and American countries prefer larger ones; and Russians prefer skinned onions. The international market has strong demand for deep-processed products of onion, garlic, and ginger. Depending on the size of the onion, you can use a classification device to sort it. By adjusting the classification aperture, the ingredients are classified and screened reasonably, so as to improve the efficiency and enter the next processing step.

As we all know, except for one-head garlic, only one layer of skin is required. The number of cloves of garlic includes two layers. One layer is the skin, and the other layer is wrapped on each garlic clove. This kind of meticulous manual work that requires patience will inevitably cost a lot of manpower and time. So, how do these garlic deep-processed products peel the garlic?

At present, the garlic peeling machine on the market mainly uses high-intensity airflow, motor rotation, and water softening to peel garlic. In order to keep the ingredients from qualitative change, the best way is to use an air compressor to generate a strong airflow to form a cyclone. The outer membranes such as garlic cloves and shallots are peeled off.

When the garlic and onions are peeled, it becomes one of the popular foods. Therefore, garlic equipment, slicing and shredding equipment, drying equipment, grinding equipment, etc. have appeared one after another to provide convenience for food processing. Recently, peeled and quick-frozen garlic in small packages is extremely popular in Europe, America, and Japan. European and American countries have simply peeled and quick-frozen garlic imported from China. The garlic grains appear in small packages in supermarkets, restaurants, and hotels, and their value doubles. In addition, after the garlic is extracted, the garlic residue can also be produced and processed into garlic powder, so that the garlic can be fully utilized. It is understood that each year, the instant noodle industry alone requires about 30,000 tons of garlic powder. Garlic powder is a premium condiment. Not only that, garlic processed products such as garlic powder and garlic oil are very popular.

It can be seen that there are few garlic processed varieties in our country, and the product has low scientific and technological content and added value, and has not been fully developed and used. Nowadays, it is imperative to speed up the deep processing of garlic, ginger, and onion to produce refined products. With the continuous innovation and surpassing of the food processing industry, new and convenient processing machines are emerging endlessly, and the market development prospect is obviously broad.

Fengxiang Catering Equipment Co., Ltd. has 13 years of industry experience and has provided fruit, vegetables, and meat products to thousands of customers, such as canteens of large, middle and primary schools, canteens of enterprises, central kitchens, catering chain enterprises, clean food distribution centers, and agricultural products companies Processing machinery and a complete set of production lines, at the same time also cooperate with domestic and foreign enterprises to become a leading brand in food machinery.