Since the market reform, the deep processing industry in developing countries has ushered in a golden period of development. As a food raw material, corn has a huge processing market, but the corn processing industry is still stuck in traditional processing methods, and the era of large-scale integration has not yet arrived.

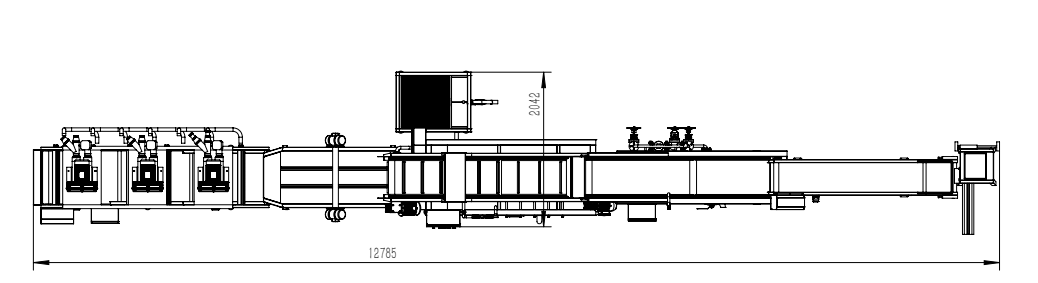

In order to improve the production efficiency of the corn industry and increase the added value of products, our company has launched an automatic corn production line. The main equipment includes corn thresher, blanching machine, washing machine, dewatering machine and air dryer.

【Corn thresher】

This machine can separate the corn from the straw, the threshing depth is adjustable, it is driven by a special motor, controlled by a frequency converter, and it is shock-resistant.

【Corn blanching machine】

This machine can quickly freeze fruits, vegetables and other products before dehydrating. With steam input automatic temperature control solenoid valve device, manual steam input device and temperature control detector, it can automatically adjust to keep the temperature within the applicable range.

【Corn bubble cleaning machine】

This machine combines three cleaning methods: bubble cleaning, cyclic surfing and high-pressure spraying to quickly cool the scalded materials. The machine is equipped with a circulating filter system and an activated carbon filter device to save water and sterilize in one step.

【Corn Vibration Drainer】

This machine can vibrate and drain the cleaned corn kernels and transport them to the next processing procedure.

【Corn air dryer】

The high-pressure blower is used to dry the water on the surface of the corn, and the step design can make the material roll, and the air-drying and dehydration can be carried out more comprehensively for the next processing procedure.