Mechanical threshing of corn can be a very efficient way to separate the grain from the stalks and husks, Corn mechanical threshing, cleaning, and drying are critical processes that determine the quality and quantity of the final product. but there are several important factors that need to be considered to ensure a successful harvest. Here are some matters needing attention in the process of mechanical threshing of corn:

1.Harvest Timing: Corn should be harvested at the right time to ensure the highest yield and best quality. The optimal time for mechanical threshing is when the corn is fully mature and dry.

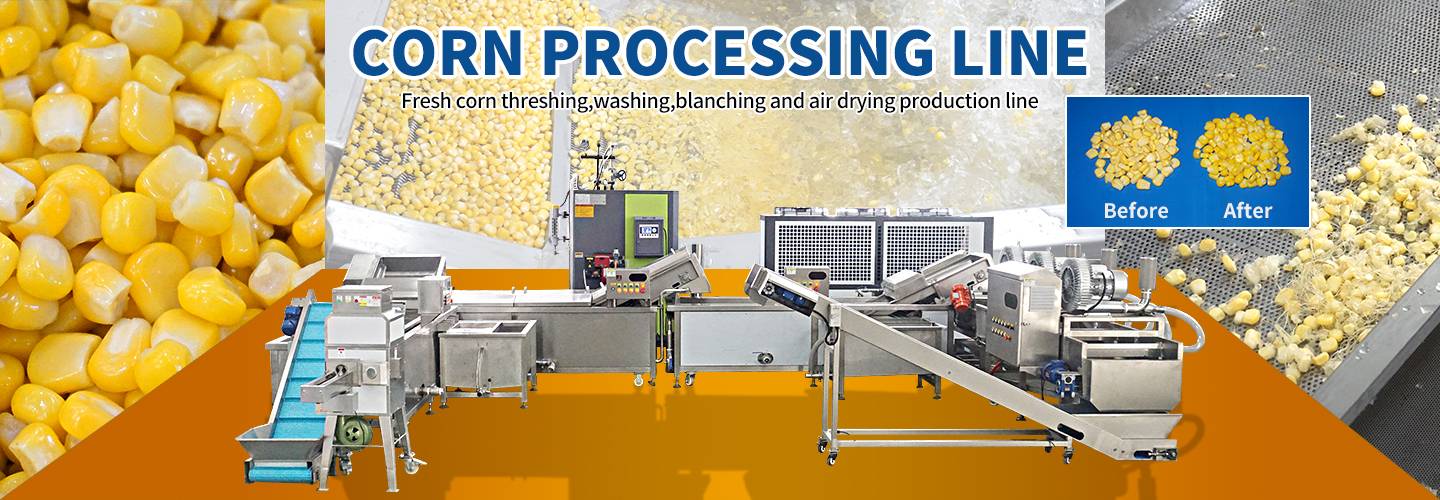

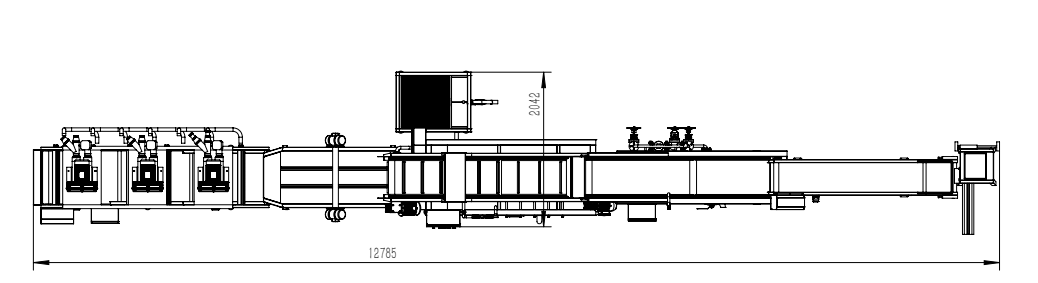

2.Machine Selection: Choosing the right machine is crucial for successful mechanical threshing. Different machines have different capabilities and efficiencies, so it's important to choose one that is appropriate for the size and condition of your crop.

3.Machine Maintenance: Before starting the mechanical threshing process, it's important to make sure that the machine is in good working condition. Regular maintenance and inspections will help prevent breakdowns and ensure that the machine is operating efficiently.

4.Cleaning: After threshing, the corn may contain impurities such as dirt, leaves, and broken cobs. It's crucial to clean the corn thoroughly to remove all the impurities. Use of grain cleaning equipment such as screens, aspirators and gravity separators can be used to remove the impurities.

5.Drying: Corn needs to be dried to a safe moisture level for storage, transportation and to prevent the growth of molds and fungi. It's important to use proper drying techniques and equipment to avoid damaging the corn. High-temperature drying may cause the corn to crack and break, leading to quality loss.

6.Moisture Content: Corn that is too wet can be difficult to thresh, while corn that is too dry can result in excessive grain damage. It's important to monitor the moisture content of the corn and adjust the threshing settings accordingly.

7.Grain Quality: Mechanical threshing can damage the grain if the machine is not set up properly. It's important to adjust the threshing settings to minimize grain damage and ensure high-quality grain.

8.Safety: Mechanical threshing can be dangerous, so it's important to follow all safety guidelines and precautions. This includes wearing protective clothing and equipment, as well as being aware of potential hazards such as moving parts and debris.

Overall, attention to detail and careful planning are key to successful mechanical threshing of corn. By considering these factors, you can ensure a successful harvest and high-quality grain.