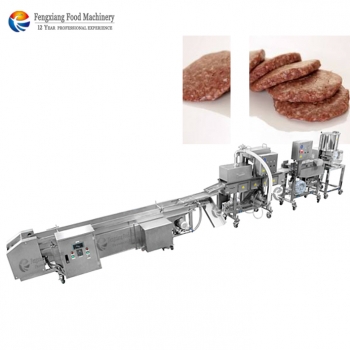

Automatic Hamburger Burger Patty Forming Making Processing Machine

forming, batter spraying, predusting (flouring), battering machine, frying and freezing.

Automatic beef burger processing line: forming, freezer and packaging.

It can make different chicken products such as the chicken nuggets, burger, chicken popcorn, chicken legs, chicken culet and so on. This line shares the reputation of high automatic, mini size and easy operation, very simple cleaning design.

This line can process diversified materials:

Meat: Poultry, beef, mutton, pork etc.

Seafood: fish, shrimp

Vegetable: Pumpkin and potato, cheese and their mixer.

The end products include the very popular hamburger, chicken nuggets, chicken or beef steak, pumpkin patty etc. It regularly becomes the most ideal choice for the small or middle scale factory, home factory and dispatching center.

Process for each finished product

|

Photos |

Name |

Processing |

|

|

1. Chicken burger Diameter 80mm Thickness: 15mm Weight:80-100g

|

1. Forming→2.Tempura battering machine→3. Breading machine→4. Frying machine→5. Air cooling→6.Freezing cold room→7. Packaging machine |

|

|

2. Chicken legs and chicken wings

|

8. Batter spraying machine→9. Drum predusting→4. Frying machine→5. Air cooling→6.Freezing cold room→7. Packaging machine |

|

|

3. Chicken nuggets Weight: 20-30g Size: 80*20*15mm

|

1. Forming→8. Batter spraying machine→10. Belt predusting →2. Tempura battering machine→4. Frying machine→5. Air cooling→6. Freezing cold room→7. Packaging machine |

|

|

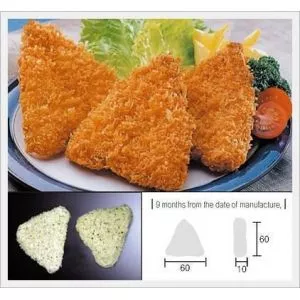

4. Chicken cutlet (chicken schnitzels) Weight: 80-140g

|

11. Cutter→12. Vacuum tumbler→13.Meat flattening machine →10. Belt predusting →2. Tempura battering machine →14. Belt predusting→4. Frying machine→5. Air cooling→6.Freezing cold room→7. Packaging machine |

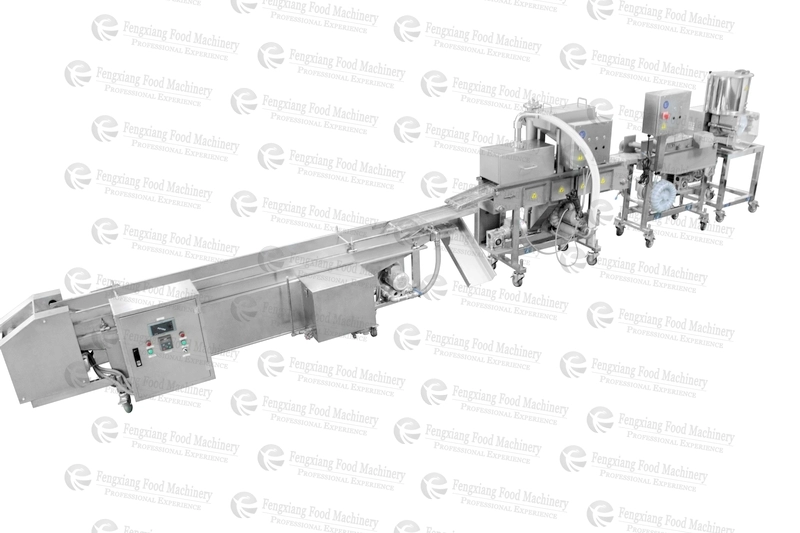

Whole machine line review,Scene Photo

Parameters:

Capacity: 2100pc/h.

Voltage: 220V 50hz

Power: 3KW

Weight: 2100KG

Dimension: 5m

Features:

1. It can make any shapes as you want, with largest diameter 120mm.

2. It can be connected with battering or frying machine if necessary.

3. Weight and thickness of final products can be adjusted, 5~12mm thick.

4. Easy operation. User just puts raw material into barrel and machine can form shapes automatically.

5. Easy for replacing forming mould.

6. Machine has automatic paper sending system.

7. Sanitary and safe. This equipment is made of stainless steel and food-grade material, which measures sanitary standard and HACCP.

8. Easy for cleaning and maitain

Note:

It can be connected to related processing step like meat mincing machine, flavoring machine, forming machine, freezing, packing machine in a whole processing line.

Hearty service:

1.Before sending the machine, we will test and adjust, so you can use directly when you get it.

2.Operating video & instruction will be sent to clients, to help them better use the machines.

3.Any problems occur while using, professional advice will be given by us.

4.All kinds of frequently used parts are supplied from us all the year round.

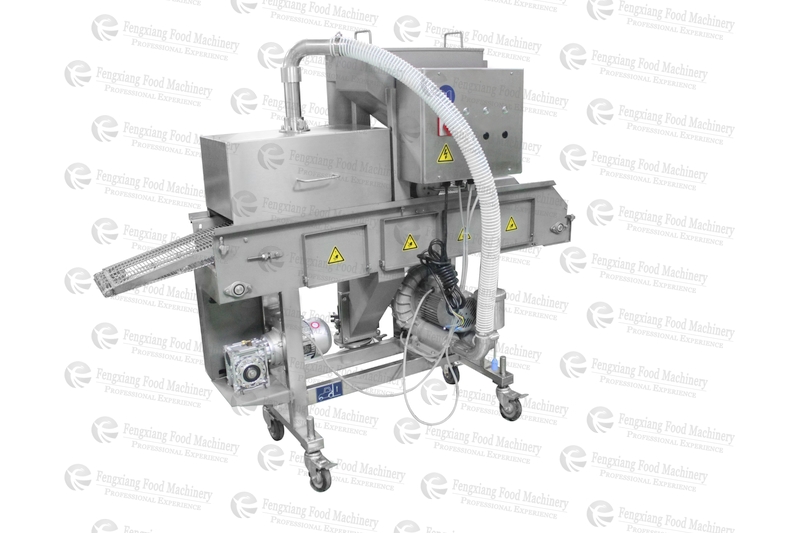

Each part of the machines line:

1.HAMBURGE MOLDING MACHINE

2.Battering Machine

3. Breading Machine

4.Frying Machine

5.Fans Cool down and drying machine

Zhaoqing Fengxiang Food Machinery Co.,Ltd. Add:NO.1-2, LANG QING XUAN, JINGTAI ROAD, ZHAOQING, GUANGDONG, CHINA

| Document | Download |