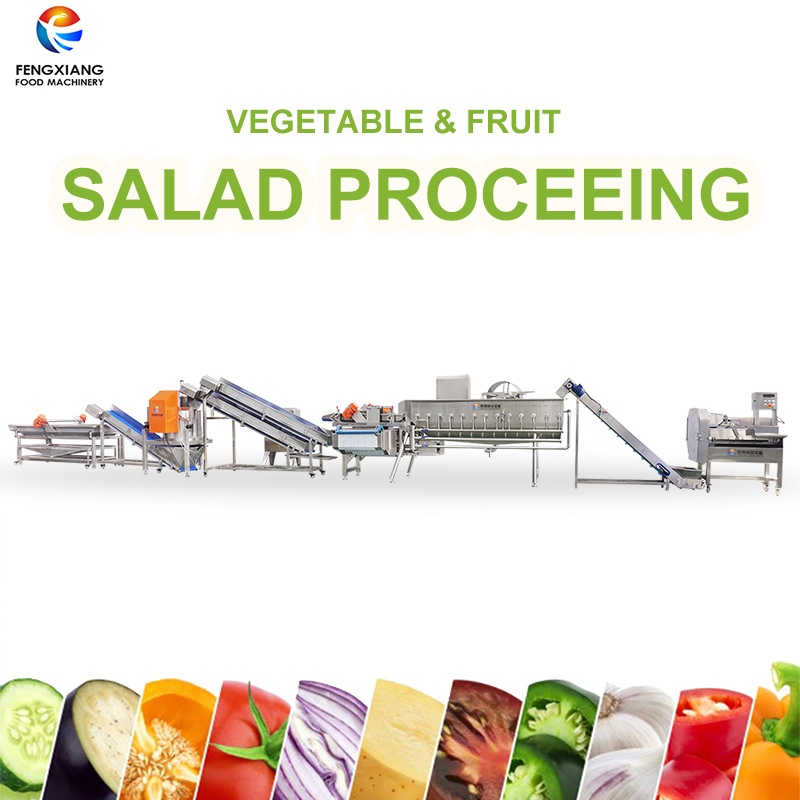

Frying production line is a widely favored equipment for making fried food. We can provide different solutions according to the different food processing needs of customers. This production line realizes the whole process of seasoning mixing-frying-degreasing, and the hoist is connected to material transportation, which is safe and reliable, and improves efficiency and output.

Parameters of Industrial Food Frying Production Line

Power of stainless steel conveyor:0.25KW

Power of de-oiling machine:2.2KW

Features of Industrial Food Frying Production Line

1. Three heating methods: steam, electricity and natural gas;

2. The machines are made of high-quality stainless steel, corrosion-resistant, and meet food safety standards;

3. The PLC control panel can set the frying time and adjust the conveying speed;

4. Automatically flip and discharge, avoid manual contact, safe and reliable;

5. It can be used as a stand-alone machine, or connected to a complete frying line or French fries, potato chip production line or banana chip production line.

Detail of Industrial Food Frying Production Line

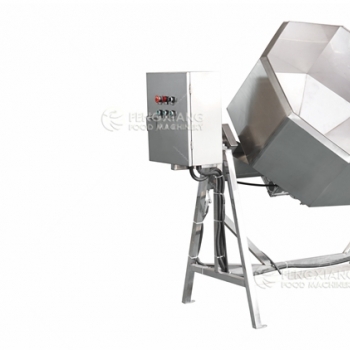

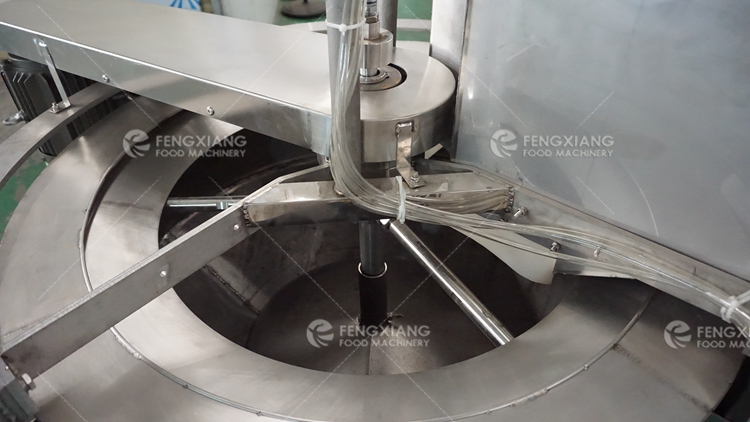

180° automatic discharging seasoning machine:

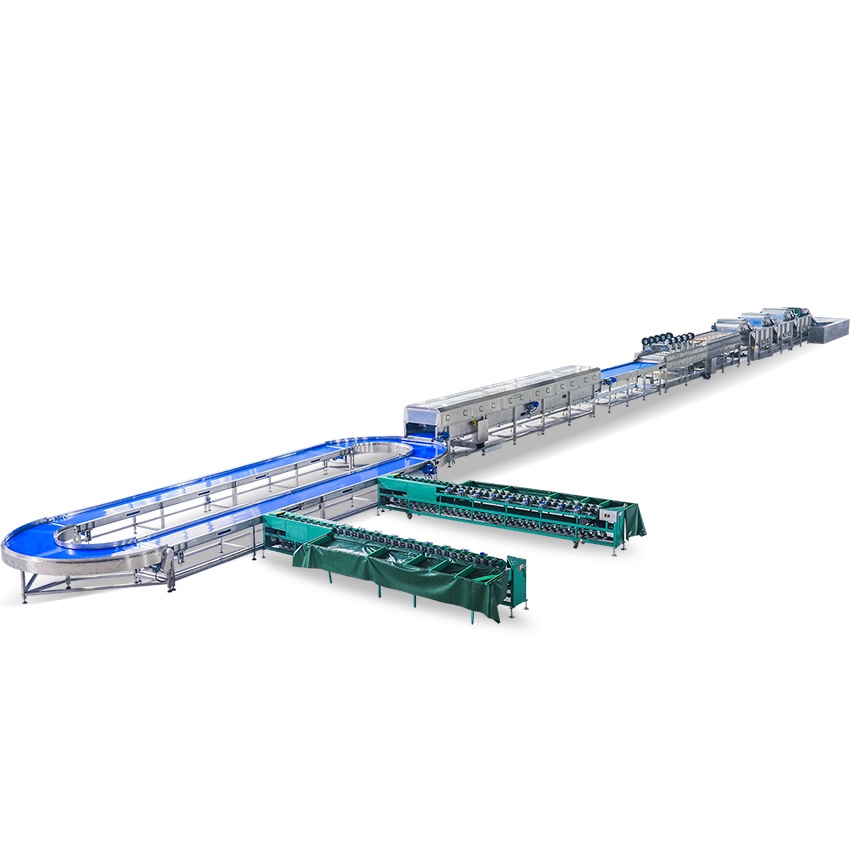

High output and controllable time frying-deoiling-conveyor production line:

PLC Control Panel

High frequency centrifugal deoiling

The size of the fryer can be customized

Equipped with a drain port to facilitate machine cleaning.

Application of Industrial Food Frying Production Line

This frying production line is mainly suitable for various kinds of fried food like meat pie. chicken nuggets, potato chips,spring rolls. peanuts and other snacks, widely used in food industry with large capacity.

| Document | Download |