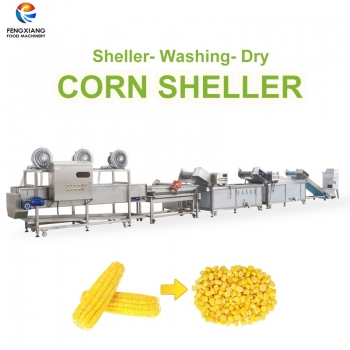

Fengxiang Industrial Sweet Corn Kernel Processing Line for Threshing Blanching Washing Dewatering Machine

The corn kernel production line can produce various corn products such as corn salad, corn snacks, corn fried products, etc. According to the customer's processing requirements, we can provide the most suitable solution equipment to achieve high efficiency, high production and full automation.The main equipment consists of corn thresher, blanching machine, washing machine, dewatering machine and air drying machine.

The Specification of Industrial Sweet Corn Krenel Processing Line

|

Machine |

Dimension |

Voltage |

Power |

Capacity |

|

MZ-368 Corn Thresher Line |

570*540*1250mm |

220V |

3.9kw |

300-400kg/h |

|

Pt-1000 Blanching Machine |

2600 x 1200 x 1700mm |

380V |

2.6kw |

500-1500kg/h |

|

WA-1000 Bubble Washing Machine |

2500*900*1140mm |

380V |

3.2kw |

700kg/h |

|

FT-1800 Vibration Dewatering Machine |

1800×850×850mm |

220V/380V |

0.5kw |

1500kg/h |

|

DM-15 Air Drying Machine |

3000x1023x11993mm |

380V |

1.5kw |

1500kg/h |

Process

Sweet corn threshing → Conveyor → Blanching → Cooling and cleaning → Dewatering → Air drying

1) Corn thresher: Separate the corn from the stalks, the threshing depth is adjustable, driven by a special motor, controlled by a frequency converter, and shock resistant.

2) Lifting conveyor: used to lift the connection of corn and blanching machine, the belt tension is adjustable, easy to clean.

3) Blanching machine: suitable for quick freezing of materials, scalding and scalding before dehydration, soaking, sterilization, disinfection, etc.

4) Bubble washing machine: Combining the three cleaning methods of air bubble, circulating surfing and high-pressure spraying, quickly cool the blanched material.

5) Air pressure dryer : adopts the high-pressure blowers to blow off water on the surface of food,rapid dehydration for the next step of processing

Detail

|

►Sweet corn threshing machine: The whole machine is made of stainless steel, and easy to movewith casters; the inverter controls the speed and the operation is simple; it is suitable for threshing kinds of fresh corn, sweet corn, waxy corn and frozen corn after thawing. |

|

►Corn blanching - cooling cleaning - dewatering process: The machine produces high-pressure bubbles through the operation of the blower, and then those bubbles in the water burst to form the impact. Blanching corn kernels in high temperature can achieve color protection, effective storage, time reduction of next cooking, enzyme protection, easy secondary processing and other effects. |

|

|

►Corn kernel air drying Follow up the corn yield and finished product requirements, and adjust the air volume and conveyor belt speed of the air dryer |

Finished Effect of Sweet Corn

| Document | Download |